Choosing the right geomembrane welding machine can be daunting. With so many options available, it’s easy to feel overwhelmed. This choice significantly impacts project efficiency and quality.

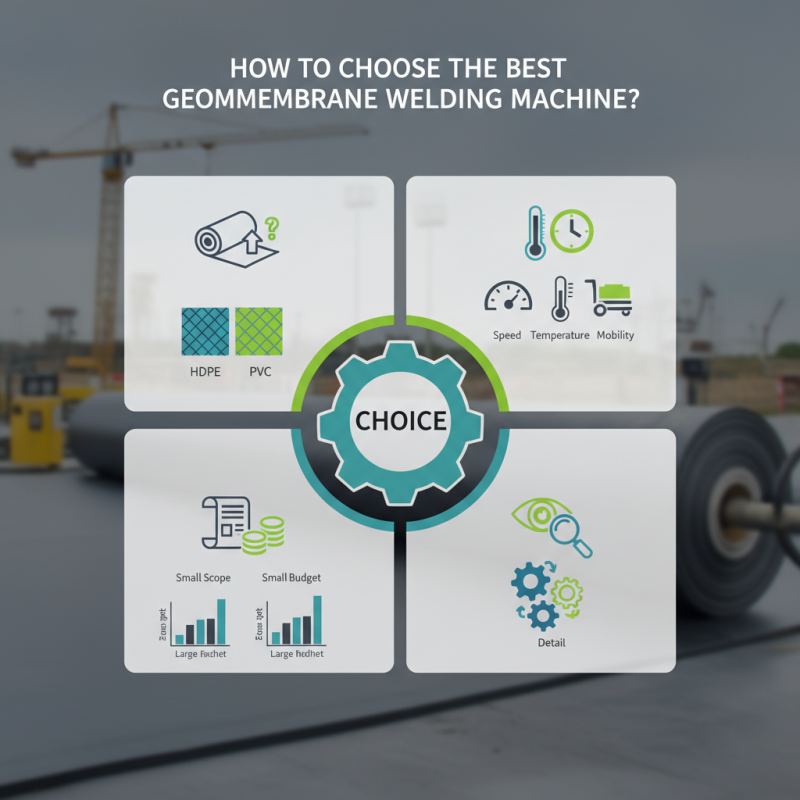

Consider the specific needs of your project. What type of geomembrane will you use? Different materials require different welding techniques. For instance, HDPE and PVC have unique requirements. A mismatch can lead to failures.

Evaluate the machine's features carefully. Look for speed, temperature control, and mobility. Some machines are lightweight and portable, while others offer advanced technology. Your choice should align with your project's scope and budget constraints. Remember, an informed decision needs time and attention to detail.

Geomembrane welding machinesplay a crucial role in the construction and environmental sectors. They are essential for creating impermeable barriers in applications like landfills, mining, and water containment. A standard geomembrane welding machine typically operates at temperatures between200°C and 300°C. This range ensures effective fusion of materials like HDPE and PVC.

According to recent industry reports, the global geomembrane market is projected to reach $3.3 billion by 2026. This growth indicates an increasing demand for robust and reliable welding technology.

Nevertheless, choosing the right machine can be complex. Numerous factors come into play, such as the type of materials, the thickness of geomembranes, and project requirements. Not all machines perform alike.

Welding quality significantly impacts project outcomes. Poor welds can lead to leaks and increased costs. Surveys show that 30% of projects face issues due to improper welding techniques. Investing in a versatile machine with adjustable parameters can minimize these risks. Awareness of potential pitfalls during selection is essential for success.

While technology continuously improves, understanding your project needs remains a priority.

Choosing the best geomembrane welding machine requires careful consideration of various features. First, look at the welding method. Some machines use hot air welding, while others use extrusion welding. Each method has its own advantages and limitations. For small projects, hot air welding may suffice. For larger applications, extrusion welding tends to provide stronger seams.

Next, consider the machine's power settings. Machines with adjustable temperature controls are more flexible and can accommodate different materials. The ability to fine-tune these settings is essential for achieving high-quality welds. Also, pay attention to the machine's weight. Heavier machines may provide stability, while lighter ones offer portability. Think about your specific work environment and project size.

Another aspect to reflect on is user-friendliness. A complicated machine might lead to errors. Look for intuitive controls, which can save time and reduce frustration. Training may also be necessary for more advanced machines. This adds to your initial cost but could lead to better outcomes. Ultimately, balancing these features against your budget will guide your choice.

| Feature | Description | Importance | Typical Range |

|---|---|---|---|

| Welding Technology | Types include hot wedge, extrusion, and RF welding | Critical for material compatibility and final product quality | Varies by application |

| Power Supply | Electric, diesel, or gas powered units | Affects mobility and operational flexibility | 110V-480V or diesel/gas |

| Temperature Control | Digital or analog temperature settings | Essential for consistent welding results | 50°C - 400°C |

| Welding Speed | The speed of the welding operation | Impacts project timelines and labor costs | 0.5 - 8 m/min |

| Weight | Weight of the machine affects transportation and handling | Heavier units may offer more stability | 20 - 150 kg |

When selecting a geomembrane welding machine, it's essential to understand the various types and their specific applications. Two commonly used machines are extrusion welders and hot wedge welders. Extrusion welders use a nozzle to melt and apply geomembrane material, ideal for thicker membranes. Hot wedge welders, however, heat two sections of membrane before fusing them together. They are more suitable for thinner materials and offer precise control.

To maximize your welding results, consider the environment. Humidity and temperature can affect the welding process. If conditions are less than ideal, this might lead to weak seams. Check the specifications of the machine carefully. Each model has its limitations and strengths based on the material and thickness.

Tips: Always practice on scrap material before commencing with actual projects. This allows you to familiarize yourself with the machine and its settings. Also, keep essential tools close by, such as a temperature gauge. It helps to ensure optimal welding conditions. Testing seams after welding is crucial for quality assurance. Small mistakes can escalate into significant issues later.

When selecting a geomembrane welding machine, several key factors can impact welding performance and quality. Temperature control is vital. An optimal welding temperature ensures strong seams. According to industry reports, welding at inappropriate temperatures can reduce seam strength by up to 20%. This emphasizes the need for precise heat management.

Another critical factor is the speed of the welding process. Slower speeds may increase seam integrity but can lead to overheating. Conversely, excessive speed might not allow proper fusion, jeopardizing the entire project. Some studies suggest that an ideal speed range is between 3-5 meters per minute. It is important to find a balance that aligns with project specifications.

Material compatibility also plays a significant role. Different geomembranes require specific settings for effective welding. Using the incorrect settings can result in poor quality seams. Reports indicate that nearly 15% of welding failures are due to material mismatches. Understanding these dynamics helps ensure better outcomes, yet many operators overlook this crucial detail. By addressing these factors, professionals can enhance the reliability of their welding operations significantly.

When using geomembrane welding machines, maintenance is key. Regular care ensures efficiency and longevity. Dirt and debris can easily accumulate in the machine's components. Cleaning these parts regularly will help prevent potential issues. Always inspect the welding tips for wear and tear; replacing them when necessary can improve quality.

One of the most overlooked aspects is calibration. Machines should be calibrated regularly for precise welding. Check the temperature settings, especially after transportation. Sometimes, these settings can change unexpectedly. Make a habit of checking these parameters before each use.

Additionally, ensure that the power supply is stable. Fluctuations can affect performance. It’s essential to use suitable extension cords and plugs to avoid malfunctions. Remember, taking the time for proper maintenance will save you from future headaches. Neglecting these tips may lead to costly repairs or replacements.

Update your browser to view this website correctly. Update my browser now